Since the pandemic started, supply chain shortages have been an ongoing problem for IT Solution Providers and Resellers. Chip shortages, COVID, labor issues, and geopolitical factors have all played a role in stressing the technology supply chain.

As the technology industry has become more globally dependent, it has become clear that no one knows precisely how long the shortages will last.

Penn State University's Dr. Michael E. Mann explains:

"The industry is very clearly dependent on globally-interconnected supply chains and distribution systems. Anything, such as COVID-19, that disrupts transportation will disrupt these supply chains and distribution systems and lead to bottlenecks and backlogs."

What's Causing the Problem

Component/Chip Shortage

It's not just chips but also resin and other elements. Demand has increased, made worse by a gap in production. There is a long lead time to create wafer factories to catch up. In addition, pricing has gone up for substrates, wafers, and operations costs. Semiconductor suppliers are passing these increases along to their customers.

For example, the largest supplier of 300mm wafers, Taiwan Semiconductor Manufacturing Company (TSMC), recently had its most significant one-time price increase of 10% for high-end semiconductors and 20% for less advanced chips.

Other suppliers have increased their prices by 5 to 15% due to the supply constraints and costs of raw materials. These types of price increases will likely continue through 2022.

Semiconductor manufacturers feel the impact of sustained demand, with wafer starts being one of the primary constraints. To improve supply, manufacturers such as Intel, Texas Instruments, and TSMC invested billions into building new fabrication plants that won't be ready until 2023.

Labor Issues

Manufacturing, distribution, and trucking are also having labor challenges. There is a labor shortage with both manufacturing skills and unfilled jobs. In 2020, the manufacturing industry lost 578,000 jobs. By 2030, the industry is anticipating that 2.1 million jobs will go unfilled.

Generational Shifts

Why is this happening? As highly skilled Baby Boomers age and leave the workforce, their younger counterparts are not replacing them. These later generations of workers do not want to work in a factory.

Transportation Crisis

There were 11 million people that worked in the transportation logistics industry who left their jobs in 2021. This departure has created a massive shortage of truck drivers needed to keep the supply chain moving.

Railroads are also having issues. The Class I freight railroads have lost 45,000 workers within the last six years. That is roughly 29% of the railroad workforce.

Phoenix Logistics Senior Vice President Robert Kriewaldt says:

"While the pandemic gets the brunt of the blame for ongoing supply chain disruptions, the logistics, and transportation labor shortage makes it increasingly difficult for companies to mitigate supply chain risk."

Geopolitical Unrest

Due to recent events, many Western companies have excluded Russia from most global high-tech supply chains. Roughly 80% of Western technology companies are leaving or reducing their presence in Russia. Companies like Dell Technologies have stopped operations or sales in Russia.

According to The decoupling of Russia: high-tech goods and components at Bruegel.org, "Targeted sanctions on specific technologies, financial sanctions and 'self-sanctioning' by private companies are effectively decoupling Russia from supplies of high-tech goods."

Shipping lines are refusing cargo to Russia and diverting vessels into other overwhelmed ports in Europe. As more volume shifts to rail, it could slow port operations. This shift will likely cause more delays to our already fragile supply chain.

Ships are the most cost-effective way of moving cargo. Moving a container by rail costs roughly twice as much as sea freight. However, last year when vendors needed mobile phones and laptops, rail became a viable option as some of the ports in China were locked down due to COVID. This lockdown has not stopped rail traffic.

Creating modern technology products uses materials from several countries. For this reason, it's unlikely that any one economy would be able to make the same products as a global network. However, two countries critical to the process are the United States and the European Union.

COVID

The pandemic has been a significant factor in the chip shortage because of COVID outbreaks. Lockdowns caused by COVID have slowed down trading routes, disrupting every link in the chain.

This case is especially true in China, a global producer and exporter of several goods the technology industry needs. China is working hard with its zero COVID approach, but any increases in COVID infections could cause authorities to tighten controls. If this happens, it will likely hinder the flow of goods in the supply chain.

Supply chain expert Olaf Schatteman told the Financial Times:

"China is digging itself into a deep hole with its zero COVID policy. As the restrictions are hurting suppliers and logistics operations, companies are moving beyond containing the current crisis and towards diversifying production locations, undermining China as the supply chain hub of the world."

IT Products

Component/Chip shortages, labor issues, transportation, geopolitical unrest, and Covid have all disrupted Original Equipment Manufacturer's supply chains. And due to the complex nature of the manufacturing process and integration, there are delays and long lead times for the end products they produce. The result for IT Solution Providers and Resellers and for the IT projects they are trying to implement, has been delays, piecemeal deliveries, or even outright cancellation of their projects which translated into dissatisfaction from their end user customers.

How Long Will It Last?

It's hard to know how long these problems with the supply chain will last. There are supply and demand issues (e.g., time to ramp up facilities) and a rise in nationalism that affects raw materials, chips, and components.

Principal industry analyst at Technology Evaluation Centers, Predrag Jakovljevic, notes that:

"The harsh reality is that the new normal we find ourselves in is harder than the pre-pandemic times. I expect that we'll see more of the same in 2022 and maybe even worse, although I hope to be wrong on this one."

There are no signs of recovery in the near future. The pandemic and other factors have caused setbacks in growth and demand. These factors were both substantial and not predicted. As a result, problems with the supply chain will likely continue. These problems will continue until the demand goes down or there is more capacity.

According to Yuh-Jier Mii, R&D Chief at Taiwan Semiconductor Manufacturing Corp, the end is still a way out. It may take 2 to 3 years for TSMC to have enough new fabrication facilities online to cover the current shortfall. He explains:

"Right now, the industry is investing a tremendous amount of capital into building extra capacity to solve this chip shortage problem. We have a much clearer picture of future demand today than we had two years ago."

While no one knows how long it will last, in the meantime, what if you had a "secret" supply chain about which few others know? How would it help your company navigate these supply chain woes?

What Can You Do About It?

Many IT Solution Providers and Resellers tend to go back to old habits even amidst supply chain chaos. When they need parts, they submit a request to their broadline general distributor.. That was the case with a Managed Service Provider (MSP) working with a NYC hospital. The MSP found the lead time was six weeks for product they needed. Not long after, they got a call from their OEM rep telling them that the six weeks was not a guarantee during these uncertain times and it may be longer.

Eventually, after checking the large channel distributors and coming back empty, they found another channel with the inventory they needed in stock. The new vendor could deliver the product the next day with expedited shipping.

HPE Pointnext Services

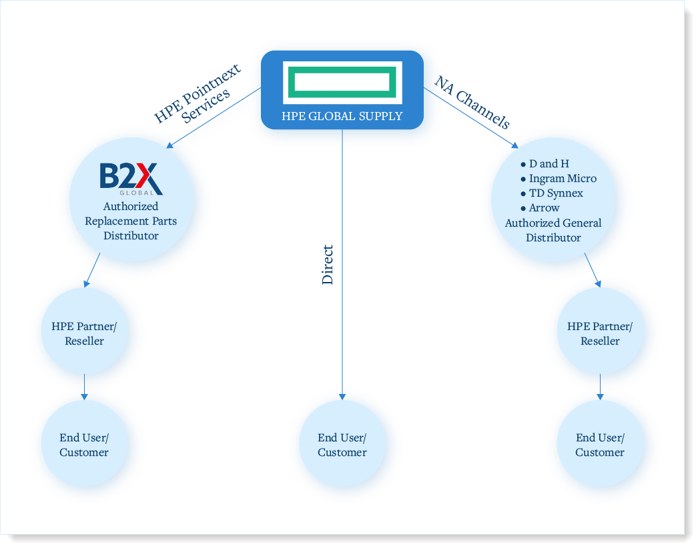

There is an authorized HPE channel that you probably didn't know exists that gives you access to products that may be in short supply. This channel, that makes up the broader HPE ecosystem, is called Pointnext. It is a distinct and separate supply chain from North American Channels with dedicated product allocations. These products are earmarked for Pointnext and packaged for that channel.

An Alternative and Authorized HPE Channel

Pointnext is part of a secure and authorized HPE supply chain. It is the IT services arm of HPE that focuses on technology components in high demand and supports the modern data center. Pointnext is also the servicing group within HPE whose focus is on products like extended service contracts.

There are three divisions within HPE Pointnext:

- Advisory and Professional Services

- Operational Services

- Education Services

B2X Global's Josh Monina describes the HPE channel ecosystem:

"Within Operational Services exists a powerful but often underutilized resource: a distribution channel that provides mission-critical products to the market daily. This unique supply chain has been reserved for service and maintenance requests."

In 2020, B2X Global partnered with HPE to use the inventory access to help IT Solution Providers and Resellers improve their end user customers outcomes.

This program aims to complement HPE's generalized distributors like TD Synnex, Ingram Micro, Arrow, and D and H. B2X acts as a complement to these traditional distributors. B2X focuses on anything that goes into a server or a storage array. These parts could include processors, hard drives, memory, network adapters, or other server/storage parts.

Why HPE Relies on the Pointnext Channel to Service Partners

Alan Wheatley, HPE Americas Replacement Parts Business Manager, explains this best:

We really rely on our distributor network because it has a much broader reach out to the resellers....(and) we are just not carrying a lot of inventory. HPE, through the corporate structure, is moving to a minimal inventory working with OEMs...(The) holding time of inventory at HPE is shortened, so we have to rely on those partners to carry inventory to support the HPE ecosystem.

Find the Parts You Need

Often, if a company searches for a part online, they look in their quote tool. These partners frequently use One Configuration Advanced (OCA) as their quoting tool for hardware. The challenge with OCA is that it doesn't have real-time inventory availability for the parts used in your solution.

With current supply chain issues, it's harder to find the parts you need through the preferred distributors. It may be because the part doesn't exist or it's not in the catalog. It could be a delay in shipping, the backorder is too long, or it's not being responded to in a fashion that you need it.

Cases like this are when resellers turn to Pointnext channel distributors like B2X Global.

When Should You Turn to B2X?

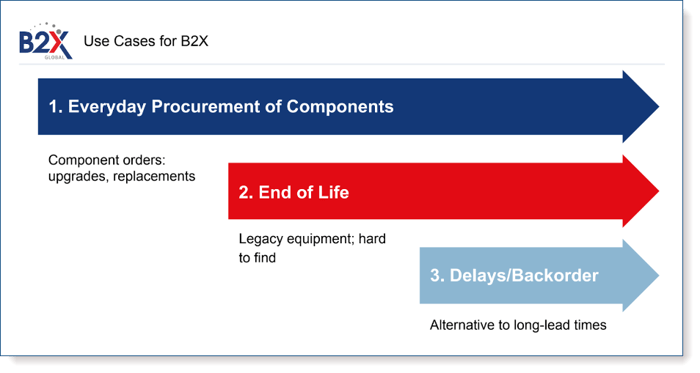

B2X offers a unique class of authorized distributors with access to a robust and separate supply channel. Partner with B2X when:

- Required parts quantity is zero, or their ETA is unknown

- Needing products that are discontinued or have reached end of life (EOL) and no longer show up in your distributor's catalog

- You desperately need faster delivery on backorders

Pointnext is a separate supply chain with authorized HPE parts distributors and HPE parts depots throughout the world. It is a different HPE channel with a different focus and may save you when your primary distributor cannot help.

Pointnext is a separate supply chain with authorized HPE parts distributors and HPE parts depots throughout the world. It is a different HPE channel with a different focus and may save you when your primary distributor cannot help.

Support More Projects With Confidence

With B2X, so many of the products you need are in stock and ready to ship. You also have immediate access to better discounts and higher margins on current, end-of-life, and constrained products.

Access to hard to source parts allows you to support projects already in the field. B2X allows you to access HPE’s global supply in addition to its own HPE inventory located in the USA.

This access is a life saver for IT Solutions Providers and Resellers managing backorder reports and requiring answers to questions such as:

- Will supply ever be available?

- Has the supply been reduced?

- Is the lead time we need available?

- Are parts actually coming?

- Is it the same product as what we expect or a replacement?

This struggle is what leads resellers to Pointnext Replacement Parts Distributor partners like B2X Global.

Optimize Your Internal "Supply Chain"

With current supply chain issues, it is easy for resellers to make commitments they cannot deliver on. This situation leaves you open to looking foolish or leaving an impression things are out of control. Now, B2X gives you another option, allowing you to source parts you cannot access anywhere else. That puts the power back in your hands.

IT Solution Providers and Resellers come to B2X most of the time because of availability. By working with B2X, you access 10,000 plus SKUs and corresponding inventory and years of HPE authorized technical expertise.

When Should You Turn to B2X?

Companies should have a primary distributor partner for ordering equipment for new projects. But what happens when you need parts for projects and systems that are already deployed and operating in the field? A company like B2X can complement that distribution relationship. If you don't have both, you're not taking full advantage of HPE's resources.

As an HPE Authorized Replacement Parts Distributor, B2X is not restricted to one customer segment - HPE RPB partners can sell products to distributors, resellers, and end user customers..B2X can support anything deployed in the field. That means anything shipped from distribution—once it's shipped, it's fair game.

Forgot something during a deployment? B2X can support you with everything that goes into a server, and help with storage unit parts as well.

Since 2020, we all have witnessed how the unexpected can happen at any time. We saw unprecedented challenges in the supply chain and distribution channels for HPE's most popular products. The Pointnext network allows HPE and its partners to respond to the needs of their customers. This availability helps customers adapt and thrive during times of chaos.

Why B2X Global?

B2X Global is the only distributor within Pointnext with a 100% focus on supporting the HPE partner community. They have decades of experience working with over 1,600 resellers. B2X is the North American Channel's preferred parts distributor with daily interaction with HPE's Channel Development and Support team.

B2X can access the Pointnext IT supply chain offering resellers and service providers a way to improve their productivity and profitability.

Multi-cloud networking provider Aviatrix's Chief Operating Officer John Jendricks remarks:

"B2X earned our business due to their proven expertise in the sourcing, integrating, and delivering specialized server hardware and components...(and) as soon as things were up and running, it was their customer support and collaborative relationship that made it a really successful partnership."

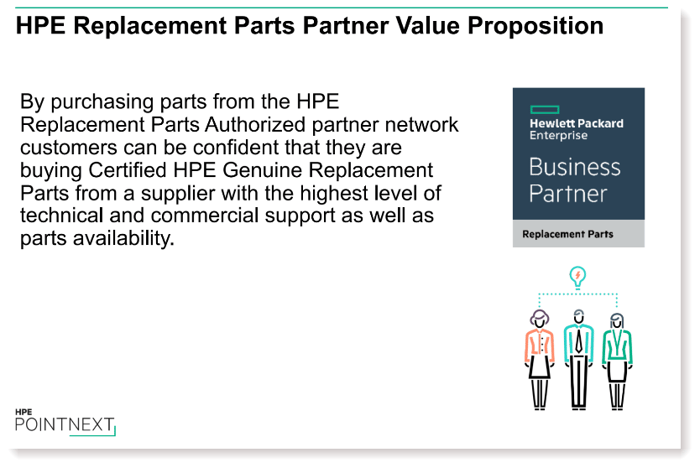

Round Out Your Resources

Resellers need to round out their resources by not relying on a single supply chain for parts. B2X Global offers HPE Replacement Parts sourced directly from HPE themselves. With this, you can be confident you're getting Certified HPE Genuine Replacement Parts and the highest level of technical and commercial support.

And their technical experience allows resellers to work with partners to design solutions based on availability.

B2X Global is the missing piece of your supply chain puzzle.